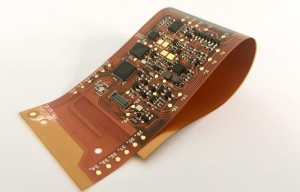

2 layer flex pcb with FR4 Stiffener

A 2-layer flexible PCB (Printed Circuit Board) is a circuit board consisting of two flexible substrate layers on which conductive traces, vias, and other components are mounted. These PCBs are designed to be flexible and can adapt to different shapes and angles, making them suitable for applications where flexibility and space constraints are important.

Some common applications for 2-layer flex PCBs include:

Consumer Electronics: Flexible PCBs are used in smartphones, tablets, and wearable devices to connect components and provide the flexibility to bend and fold.

Automotive Electronics: Flexible PCBs are used in automotive applications to create custom-shaped circuits for sensors, lighting, and control modules in tight spaces.

Medical Devices: Flexible PCBs are used in medical devices, such as wearable health monitors and medical imaging equipment, where flexibility and compactness are critical.

Aerospace and Defense: Flexible PCBs are used in aerospace and defense systems because of their lightweight and adaptable properties, with applications ranging from avionics to military equipment.

Industrial Control: Flexible PCBs are used in industrial control systems because they can withstand environmental stress and fit into compact spaces.

Overall, 2-layer flexible PCBs provide versatile solutions for a variety of industries where space constraints, weight considerations, and flexibility needs are critical factors in the design and performance of electronic devices and systems.

According to IPC 6013, Board type including

Type 1 Single-Sided Flexible Printed Boards

Type 2 Double-Sided Flexible Printed Boards

Type 3 Multilayer Flexible Printed Boards

Type 4 Multilayer Rigidi and Flexible Material Combinations

At earlier stage, technical support is important for you to proceed the designs, from line width/spacing to stackup (material selection), especially for impedance control value calculation, Please feel free to contact us for any questions.

Bolion recommend that all new projects should have prototypes confirmation before mass production. Prototype is important for technology review, meanwhile, it would be helpful to get the most competitive price for mass production and resonable lead time.

From Quick-Turn prototype to series production, we are doing our best to meet customers’ lead time requirement.

| Description | FPC Prototype (≤1m²) |

FPC Standard Turn (≥10m²) |

SMT Assembly |

| Single-sided FPC | 2-4 days | 6-7 days | 2-3 days |

| Double-Sided FPC | 3-5 days | 7-9 days | 2-3 days |

| Multilayer/Airgap FPC | 4-6 days | 8-10 days | 2-3 days |

| Rigid-Flex Board | 5-8 days | 10-12 days | 2-3 days |

| * Working Days | |||

Following your shipping instruction if there is any, if not, we will accordinate with the most competitive shipping terms, FedEx, UPS, DHL. Xiamen Bolion is experienced with all the paperwork for customs.