The aerospace industry relies heavily on a wide array of components, parts, and equipment. From aircraft dashboards to communication systems on unmanned spacecraft, these devices often require the use of PI heaters or flex pcb heater systems to prevent components from freezing in sub-zero temperatures, eliminate moisture from semiconductors and circuits, or provide thermal management solutions. Below are several reasons why aerospace manufacturers choose PI heaters when designing and producing products and systems.

PI heaters are extremely lightweight, making them ideal for aerospace applications where every additional gram can affect how aircraft, drones, or spacecraft operate in the air or in space. As electronic components and controls continue to miniaturize, the slim profile of polyimide heaters becomes increasingly advantageous.

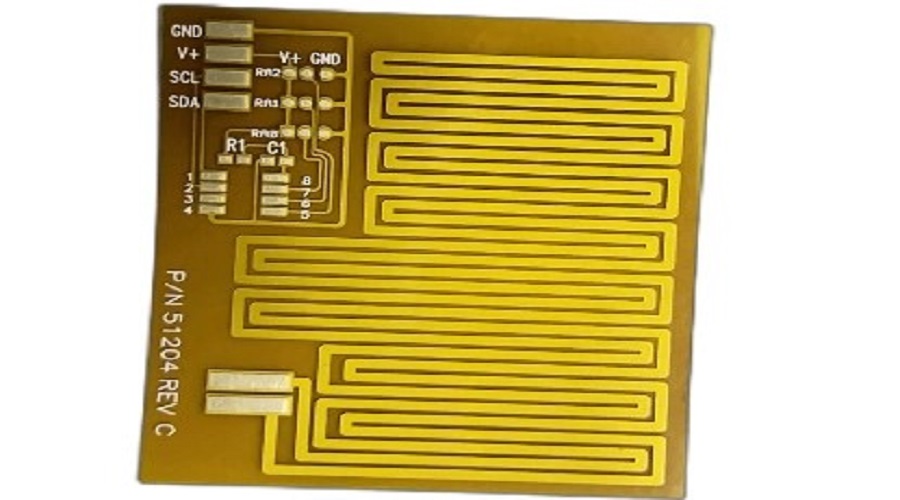

In addition, polyimide heaters offer excellent flexibility. They can bend to fit a wide range of curves and irregular surfaces encountered in aerospace environments. These heaters can be manufactured in very small sizes, and their shapes can be custom-designed to accommodate confined spaces where targeted heating is required.

Aerospace systems use a variety of sensors for purposes such as tracking movement or transmitting critical data. These sensors are often highly sensitive and can be disrupted by any type of gas emission near them. When manufacturing parts and assemblies that include or are placed near sensors, aerospace engineers must carefully select materials that do not release gases under heat, friction, or aging.

PI heaters exhibit minimal gas content within their molecular structure. As a result, even under heat or prolonged inactivity, the materials in polyimide heaters emit virtually no gases. This ensures that sensitive sensors continue to function properly without interference.

Not all aerospace equipment is used within Earth's atmosphere. Communications satellites, crewed and uncrewed spacecraft, and launch systems must operate in the vacuum of space. In these harsh environments, where air is absent, extreme cold can damage components.

Because convective heating is not possible in a vacuum, thermal management becomes a significant challenge. In such cases, polyimide heaters are used to provide reliable thermal transfer. By bonding a pi heater directly to the component, devices can quickly achieve and maintain the operational temperature needed, whether continuously or intermittently. These heaters also deliver uniform thermal distribution, avoiding hot spots or isolated cold areas.

Another key advantage of PI heaters in aerospace applications is their resistance to radiation. Ultraviolet radiation from the sun, as well as gamma rays from neutron stars, pulsars, and supernovae, can pass through outer space and upper atmospheres. These high-energy rays can impair the function of both manned and unmanned spacecraft, aircraft, and other systems.

When polyimide heaters are used, their polyimide material resists both UV and gamma radiation, ensuring that thermal management systems continue to operate efficiently. Furthermore, PI heaters offer an additional layer of protection for nearby components, shielding them from the damaging effects of cosmic radiation.

PI heaters and polyimide heaters have proven to be indispensable in aerospace applications due to their light weight, flexibility, low outgassing, vacuum compatibility, and radiation resistance. These attributes make them an essential component in the design of modern, reliable aerospace systems.

European Battery Show 2025 Recap – Ready to Take Your Battery Projects Further?

17 Jun 2025

From June 3rd to 5th, the European Battery Show was grandly opened in Stuttgart, Germany. As a professional FPC and CCS/IBB manufacturer, Bolion showcased its electrification vision at the European Ba...

European Battery Show 2025 Recap – Ready to Take Your Battery Projects Further?

17 Jun 2025

From June 3rd to 5th, the European Battery Show was grandly opened in Stuttgart, Germany. As a professional FPC and CCS/IBB manufacturer, Bolion showcased its electrification vision at the European Ba...

Applications and Advantages of Flexible PCB Heaters

09 Jun 2025

A flexible PCB heater, also known as a flex PCB heater, is a type of heating material with a flexible structure that can be used in a wide variety of applications. This article outlines the uses and b...

Applications and Advantages of Flexible PCB Heaters

09 Jun 2025

A flexible PCB heater, also known as a flex PCB heater, is a type of heating material with a flexible structure that can be used in a wide variety of applications. This article outlines the uses and b...

Herzlich willkommen! | Join Bolion Tech in the Battery Show Europe 2025: Where Global Battery Innovation Connects

23 May 2025

In June, beneath the skies of southern Germany, the morning mist along the Rhine is gradually lifting in Stuttgart. As the first rays of sunlight pierce through the glass curtain walls of the Messe St...

Herzlich willkommen! | Join Bolion Tech in the Battery Show Europe 2025: Where Global Battery Innovation Connects

23 May 2025

In June, beneath the skies of southern Germany, the morning mist along the Rhine is gradually lifting in Stuttgart. As the first rays of sunlight pierce through the glass curtain walls of the Messe St...

Call us on:

Call us on:  Email Us:

Email Us:  No.198 Houxiang Road, Haicang District, Xiamen, China

No.198 Houxiang Road, Haicang District, Xiamen, China